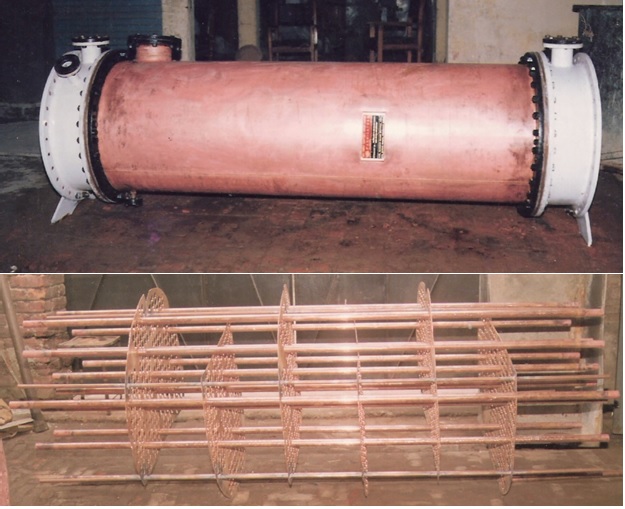

HEAT EXCHANGERS

We fabricate shell & tube heat exchangers like Reboiler, Condenser, Evaporator (Both Falling Film and Forced Film), Calendria etc. are designed by our engineers in accordance to the TEMA/ASME/IS Standards. These heat exchangers are extensively used in Distillation plants, chemical plants, Pharmaceutical plants and various process industries. Below mentioned are the detailed specifications of our range of heat exchangers.

- Capacity: Heat Transfer 1m2 - 200 m2 or as per customer requirement or process parameters.

- Type: Fixed head and U tube.

- Tube Type: Plain only.

- Designed and Fabricated as per IS:2825, ASME Sec VIII Div 1, TEMA Standard

- Material Used in the Shell: carbon steel, stainless steel, alloy steel, copper and other alloys.

- Material Used in the Tube: aluminium alloy, brass, copper, carbon steel, and stainless steel.